Mobile Phone Electrostatic Discharge Problems and Solutions

2020-05-20Problems that can be aused by electrostatic discharge of mobile phones

The problems in ESD electrostatic discharge immunity test are mainly shown in the following aspects.Firstly, the phone call is interrupted; secondly, the ESD electrostatic discharge causes some functions of the phone to fail, but the failed functions can be restored after the electrostatic discharge process is over or after restarting the phone.

The phenomenon includes for

1.Abnormal screen display

2.There is a whistling sound or the sound disappears during a call;

3.Loss of key function or touch screen function;

4.False alarms in mobile software

5.The mobile phone automatically shuts down or restarts。This problem can occur either during a call or during standby.

The reason for these phenomena is the failure or damage of the mobile phone caused by electrostatic discharge.Due to the damage of some components, some functions of the mobile phone cannot be restored after restarting, such as the camera function or the mobile phone cannot be turned on again after the automatic shutdown.When testing with the charger connected, the charger may also fail, damage or even explode.

Solutions to Cell Phone Electrostatic Discharge Problems

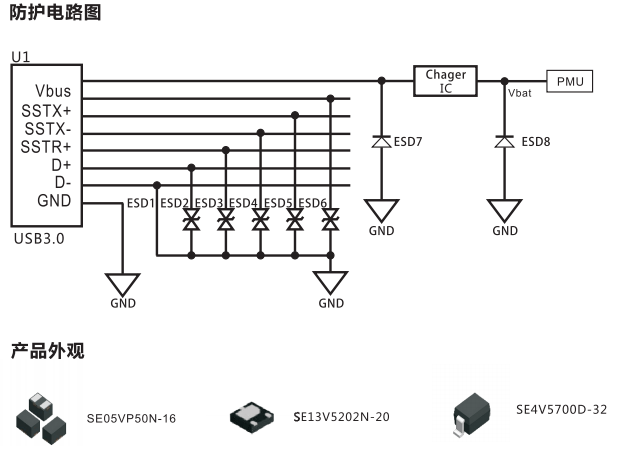

When designing cell phone circuits, using devices with high electrostatic sensitivity level, reasonable arrangement between devices and leads, and adding efficient electrostatic protection components in PCB circuits are effective measures to solve the problem of electrostatic discharge interference.Electrostatic discharge circuit protection device supplier Socay takes cell phone USB port electrostatic discharge protection as an example and introduces a high reliability ESD electrostatic diode for the application of.

Using a small size and high power ESD device on the USB Vbus end can pass surges above 300V (IEC 61000-4-5 1.2/50us-8/20us).

The maximum working voltage of ESD is 13.5V, which can meet different standards of high-voltage fast charging technology.

Use a small-sized high-power ESD at the Vbat end with a working voltage of 4.5V for secondary protection.

ESD protection of other high-speed differential communication lines use low inter-electrode capacitance of 0.35pF, which can meet high-speed communication transmission.

Socay Electronics: Components ESD Suppressor

ESD1~6:【SEO5VP50N-16】 Vwm:5V;C(f=1MHz):0.35pF;Vesd:8KV/15KV;

ESD7:【SE13V5202N-20】Vwm:13.5V;C(f=1MHz):2000pF;Vesd:30KV/30KV;

ESD8:【SE4V5700D-32】Vwm:4.5V;C(f=1MHz):70pF;Vesd:30KV/30KV;

It is not enough to design electrostatic protection for mobile phone PCB circuits. Before it is officially put into production, it needs to pass the electrostatic ESD anti-interference test under the conditions that meet the IEC610000-4-2:2004 / GB/T 2147.2-2008 test standard.Socay can provide you with one-stop service from solution design, device selection, solution testing and rectification. To learn more about electrostatic discharge protection solutions, please go directly to Socay's website to consult online customer service http://www.socay.com/.